Practical Batch Process Management

Contents:

Processing cells and flexibility. Parallel and sequential operations.

Purchase Practical Batch Process Management - 1st Edition. Print Book & E- Book. ISBN , Practical Batch Process Management. Book • Authors: Mike Barker, Jawahar Rawtani and Steve Mackay. Browse book content. About the book. Search in.

Sequencing as a time series of events. Automatic start-up and shut-down. Role of discrete signals for status, safety, isolation, etc.

Concepts of sequence logic. Absolute, lapsed and implicit timing. Datatyping and structured text. Worked example on a charging operation. Decision trees and tables. Indirect addressing and parameter lists.

- Product details;

- Batch Processing and Automation;

- Review from student.

- The Anywhere, Anytime Chill Guide: 77 Simple Strategies for Serenity?

- PARENTING Guide to Toilet Training.

- Moments of Forever: Discovering the True Power and Importance of Your Life?

- Practical batch process management | UNIVERSITY OF NAIROBI LIBRARY.

Real time execution of sequences. Sequential function charts SFC.

Get Practical batch process management PDF - Infos Network Library

Interface between sequencing and function blocks for analogue control. Pros and cons of procedural vs configurable approaches. Plant structures and physical equipment models. Major equipment items MEI as units and constraints on unit boundaries. Shared resources and contention handling, eg inter-vessel transfers.

Process management class lectures_136863297-Practical-Batch-Process-Management

Procedural models and structures. Constraints on operation and phase boundaries.

Design for common and parallel operations. Batch failure and recovery options. Case study on model decomposition.

Editorial Reviews

Demonstration of functionality of proprietary batch automation system. Batch specific aspects of application software projects: Turnkey projects and time scales.

User requirements specification URS: Physics, Mechanics, layout, Reliability, Packaging is the 1st accomplished connection with gather and current the main, up to date, in-depth, useful and easy-to-use details at the physics, mechanics, reliability and packaging of micro- and opto-electronic fabrics, assemblies, buildings and structures. Download e-book for kindle: Integrating Consumer Preferences into by Wei Chen.

Construction upon the elemental ideas of selection thought, Decision-Based layout: Integrating buyer personal tastes into Engineering layout provides an analytical method of enterprise-driven Decision-Based layout DBD as a rigorous framework for choice making in engineering layout. The target of this booklet is to prepare and rfile the technical, analytical, and functional points of present-day apple processing.

No amassed works were released on processed apple items for greater than thirty years.

Download PDF by F. The aim of this wide-ranging introductory textbook is to supply a simple figuring out of the underlying technological know-how in addition to the engineering functions of composite fabrics. It explains how composite fabrics, with their helpful homes of excessive energy, stiffness and coffee weight, are shaped, and discusses the character of the different sorts of reinforcement and matrix and their interplay.

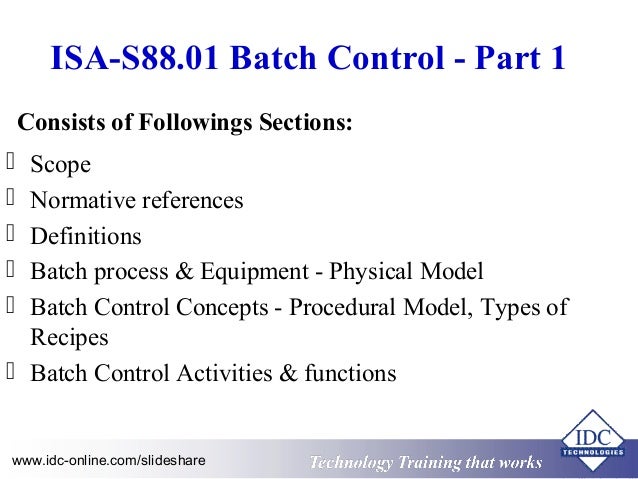

Production planning and scheduling is regarded as a high-level activity similar to production information management and recipe management. The S88 standard recognizes that these high activities are assigned to process management within a process cell. The recipe focused, combined scheduling and process management activity is referred to as recipe schedule.

Inputs for the recipe schedule come from other schedules, master recipes and resource databases. Recipe schedule is connected to higher-level planning and scheduling and is integrated with process management activities. In Mixer-2 unit, cement slurry is prepared. And finally, a batch prepared by Mixer-1 unit and a batch prepared by Mixer-2 is processed together in Mixer-3 unit. Slurry prepared in Mixer-3 after stirring is a batch of raw materials slurry, which is supplied to a stuff chest with agitator for sheeting machine.

- Methodik der empirischen Forschung (German Edition)

- Venturesome Vegan Cooking: Bold Flavors for Plant-Based Meals

- Robber Baron: Lord Black of Crossharbour: Lord Black of the Crossharbour

- Dismissed with Prejudice: A J.P. Beaumont Novel (J. P. Beaumont Novel)

- Male Nude Photography- Gabriel

- Landscaping, Your Way